They are further classified according to their custom PCB design parameters, manufacturing method, and applications needs. Printed Circuit Boards are primarily categorized based on their frequency, substrate used during manufacturing, and the number of layers. Custom PCBs emit low if not zero electronics noise. Error is unlikely on PCBs hence reduces inspection timeĨ. The design eliminates chances of short circuits and loose electronic connectionsħ. They come in compact sizes hence saving wire.Ħ. Updating the PCB is impossible once it’s printed.ĥ. Custom PCBs indicate rating for the device helping in their maintenanceĤ. Chemicals emitted during etching of CircuitĤ. Higher initial making cost than wire-wrapped circuits.ģ.

#Custom pcb install#

Easy to assemble and install since it has specific color nodes for specific connections.Ģ.

Cost-effective (Economical) hence mass production is achievableĢ. The table below outlines the merits and demerits of Custom PCB boards. They save space no matter how sophisticated a component is.

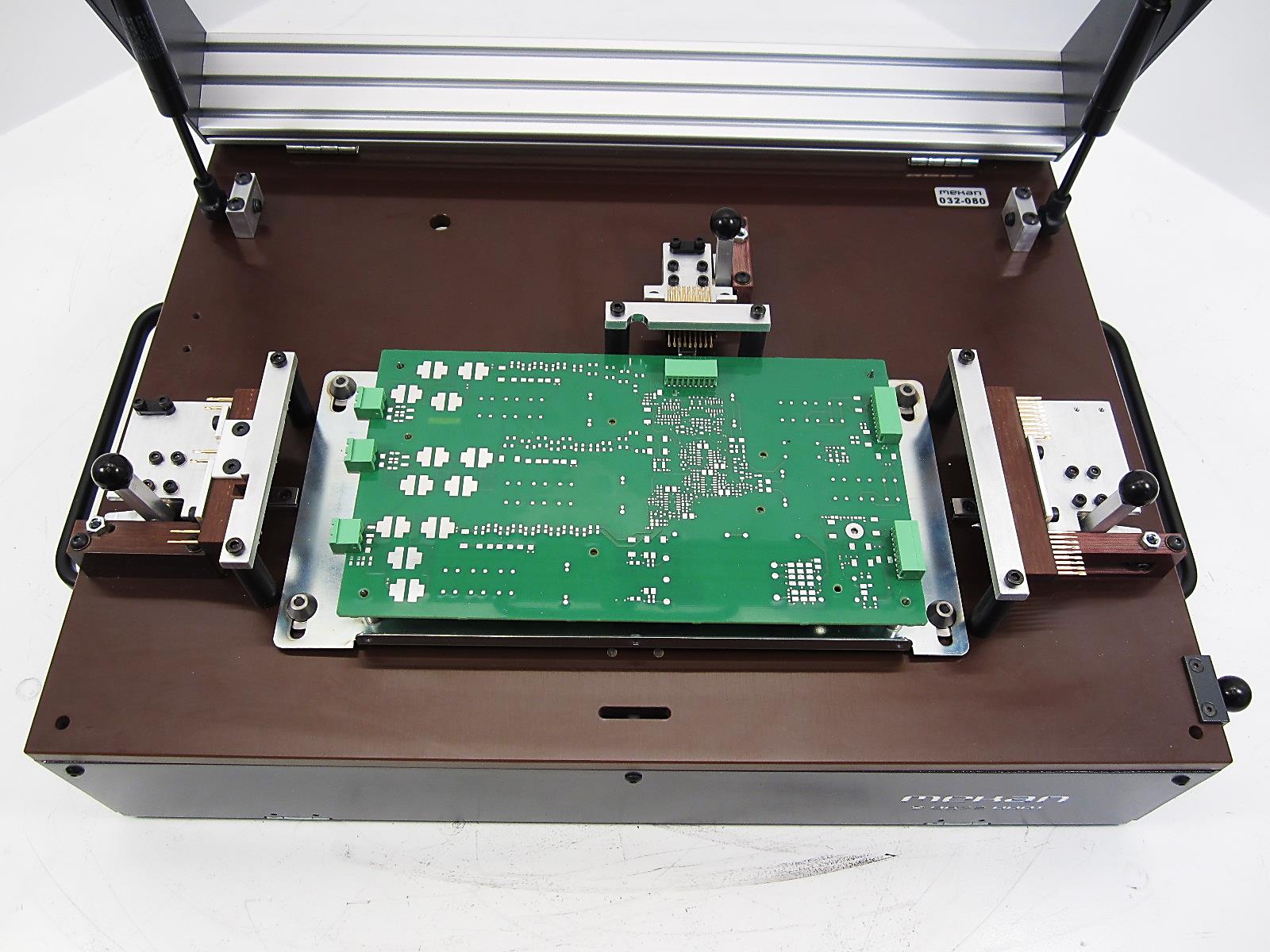

It combines electrical materials and circuits of a device. Our custom PCB basically comprises small-sized electronic materials like resistors and diodes and conductive components like copper, which are imprinted on a board (insulated). China’s Top manufacturer, assembler, and designer of Custom PCBs, MOKO Technology provides a 24 hours quick turn of PCB solutions for mass and small-scale production.

0 kommentar(er)

0 kommentar(er)